UHMW CHUTES

SST™ UHMW Chutes: The Worldwide Gold Standard

Our revolutionary UHMW chute design solves many of the material flow problems that conventional steel chutes endure. Our patented Slick Surface Technology™ (SST™) enables packages to move more effectively and efficiently.

UHMW-PE (ultra-high molecular weight polyethylene) is an extremely tough plastic with high abrasion and wear resistance. The versatility of polyethylene has made it a popular plastic for countless industrial applications that require durability, low friction, and chemical resistance.

SST™ UHMW chutes are fully customizable and scalable with few restrictions on width, side guard height, or pitch. Our custom UHMW chutes are delivered assembled and ready for installation.

SST CHUTES

Efficiently Move Packages

The low coefficient of friction of UHMW-PE enables efficient package flow and allows damp packages to maintain speed. Alternative materials, such as fiberglass and steel, can be impacted by environmental factors that cause packages to stick. UHMW has been proven to perform better than these conventional chutes.

Multiple types of UHMW-PE materials are available to support specific package sizes and weights. UHMW-PE FDA approved material is also available for food and beverage applications.

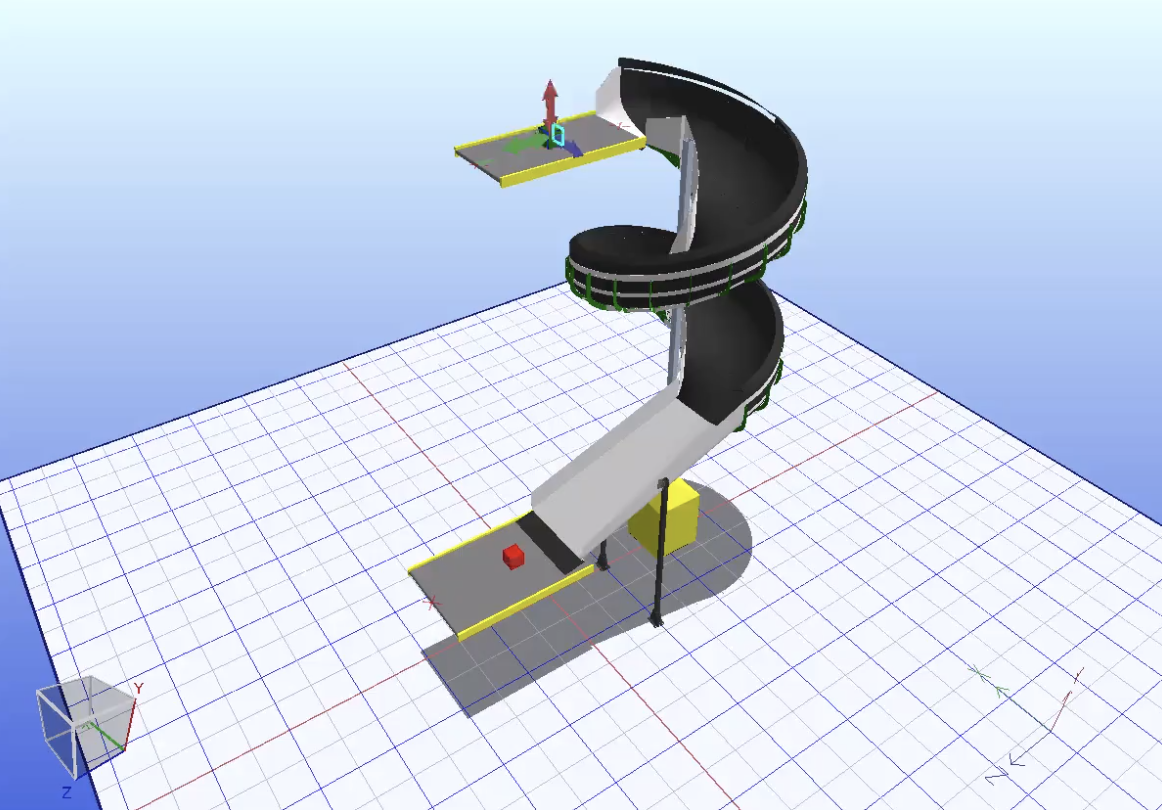

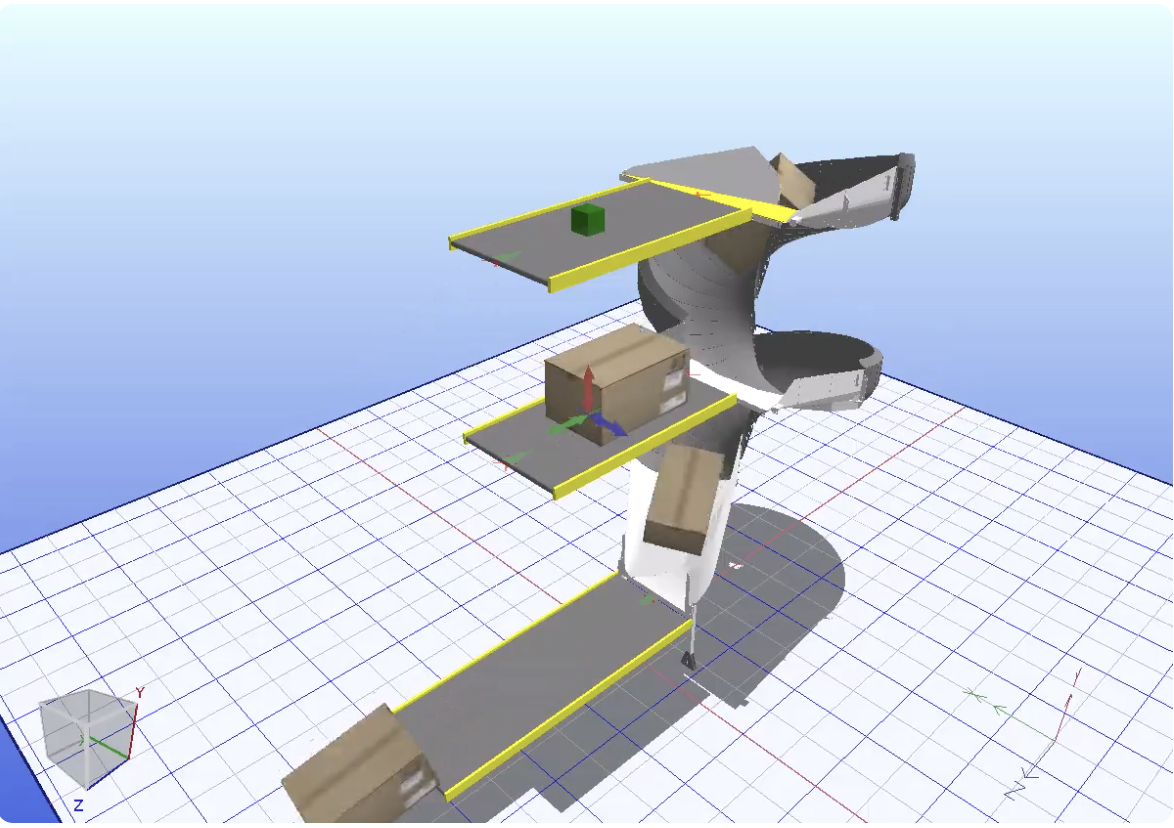

3D SIMULATIONS

Simulations

Our 3D Simulation Software allows us to model chutes prior to prototyping. If necessary, we can upload your project model to run simulations and make necessary modifications that pertain to package flow.

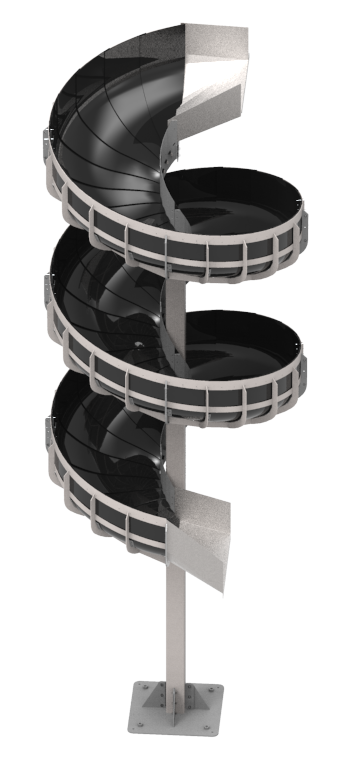

SINGLE ENTRY SST™ CHUTE

A Single Entry SST™ UHMW Chute is designed to guide materials smoothly from one entry point to a designated discharge location. Ideal for straightforward applications, it offers precision and efficiency in material handling while minimizing wear and ensuring reliable performance.

SST CHUTES

Gallery

UHMW Chute FAQs

Ultra-high molecular weight polyethylene (UHMW) is a durable, low-friction plastic known for its high abrasion resistance and exceptional strength, making it ideal for demanding material handling applications. In chute applications, UHMW ensures smooth, efficient material flow with minimal maintenance requirements.

UHMW chutes are widely used in industries like e-commerce, logistics, manufacturing, and distribution centers, where low-friction and high-durability material handling and sortation solutions are essential.

UHMW is highly abrasion-resistant, making it ideal for handling heavy use and minimizing wear in material handling applications.

Steele Solutions offers extensive customization options for UHMW chutes to meet your unique project requirements. Our representatives will work with you to design a solution tailored to your application, space constraints, height requirements, and operational goals. Our designs can also be customized to work around building columns or other structural elements.

Whether you’re starting from scratch or refining an existing concept, we’ll ensure your chute system is optimized for efficiency and functionality. Contact Steele Solutions to explore the options that best suit your operation.

Yes, UHMW chutes can be designed to accommodate multiple destinations and discharges, ensuring smooth and efficient material handling. Steele Solutions can customize chute configurations to meet the specific requirements of your facility and workflow.

The timeline for UHMW chute customization depends on your project’s specific needs and goals. Our team will work closely with you to understand your requirements, discuss your timeline, and develop a tailored solution that meets your expectations. Contact us to start the conversation and find the right solution for your project.

UHMW chutes are virtually maintenance-free and require no ongoing cleaning, waxing, or lubrication. After installation, a one-time cleaning with rubbing alcohol and a microfiber cloth prepares the chute for use. If debris, such as stickers or package remnants, becomes stuck, simply remove it with a microfiber cloth. The chute’s surface is designed to naturally maintain its efficiency through regular use, eliminating the need for continuous maintenance.

Getting started with a UHMW chute project is simple. If your site already exists, Steele Solutions can conduct a site visit to take precise dimensions. For new projects, we’ll collaborate with you to determine entry and exit elevations, height requirements, space constraints, and the ideal chute configuration.

Whether you have a fully developed concept or are starting a new project, our team will work with you to create a functional, buildable solution tailored to your needs.

Safety is at the forefront of every chute we design, ensuring compliance and reliability in even the most fast-paced environments.

We often incorporate features like custom lighting to indicate safe usage, braking mechanisms to control package movement, and safe-use design elements to protect employees working near chute discharge areas. Contact our team directly to discuss all of our available safety features.

Steele Solutions prioritizes safety by adhering to OSHA, ANSI, and NFPA standards, along with any industry-specific regulations, to ensure the secure design and operation of UHMW chutes.