SteeleTrax Structural Steel Framing Members

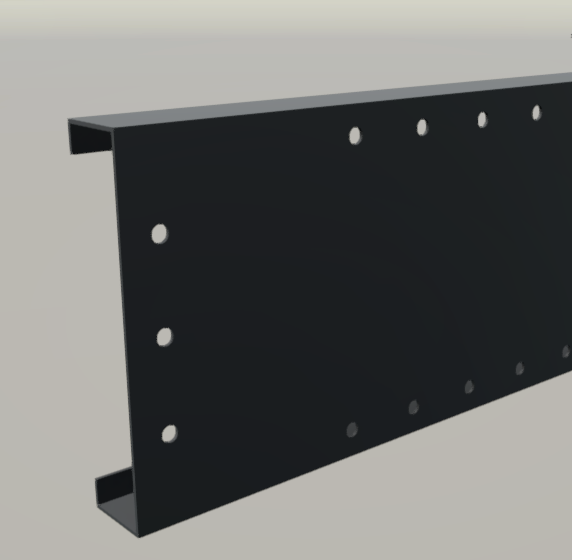

SteeleTrax is an innovative structural steel framing member designed to optimize vertical space and streamline installation in warehouse and distribution center operations.

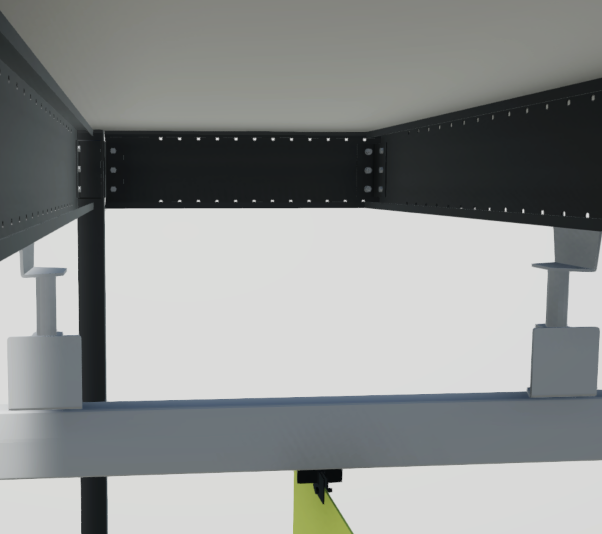

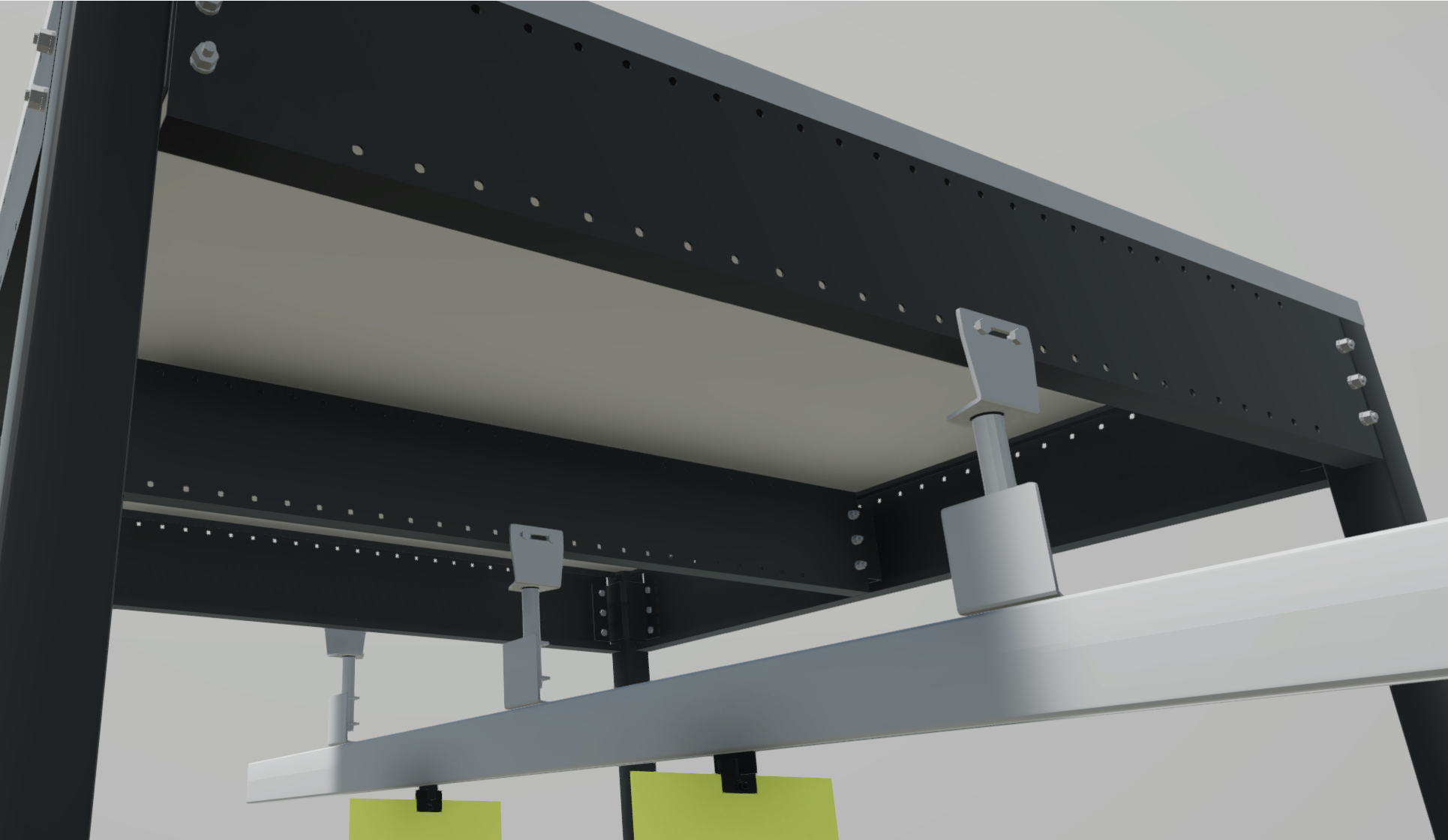

Designed for versatility and efficiency, SteeleTrax makes suspending equipment—like pocket sorter conveyors, fire suppression systems, lighting, and conduit—seamless and cost-effective.

With holes spaced 50mm on center, consistent with industry standards, SteeleTrax significantly reduces the need to manually drill holes into the framing during installation. This lowers labor costs and shortens project timelines. Available in a variety of profile depths and thicknesses, SteeleTrax was developed to further enhance the use of vertical space in material handling operations.

Suspend Equipment with Ease

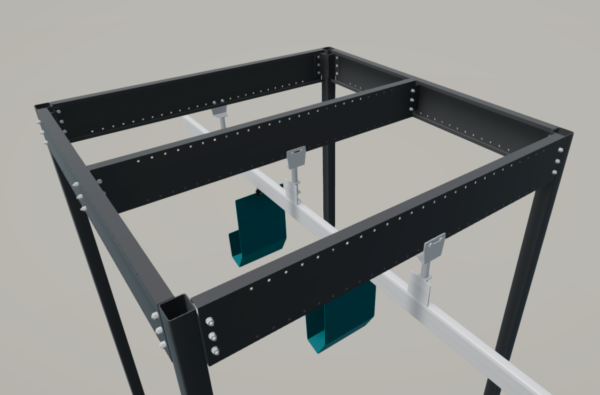

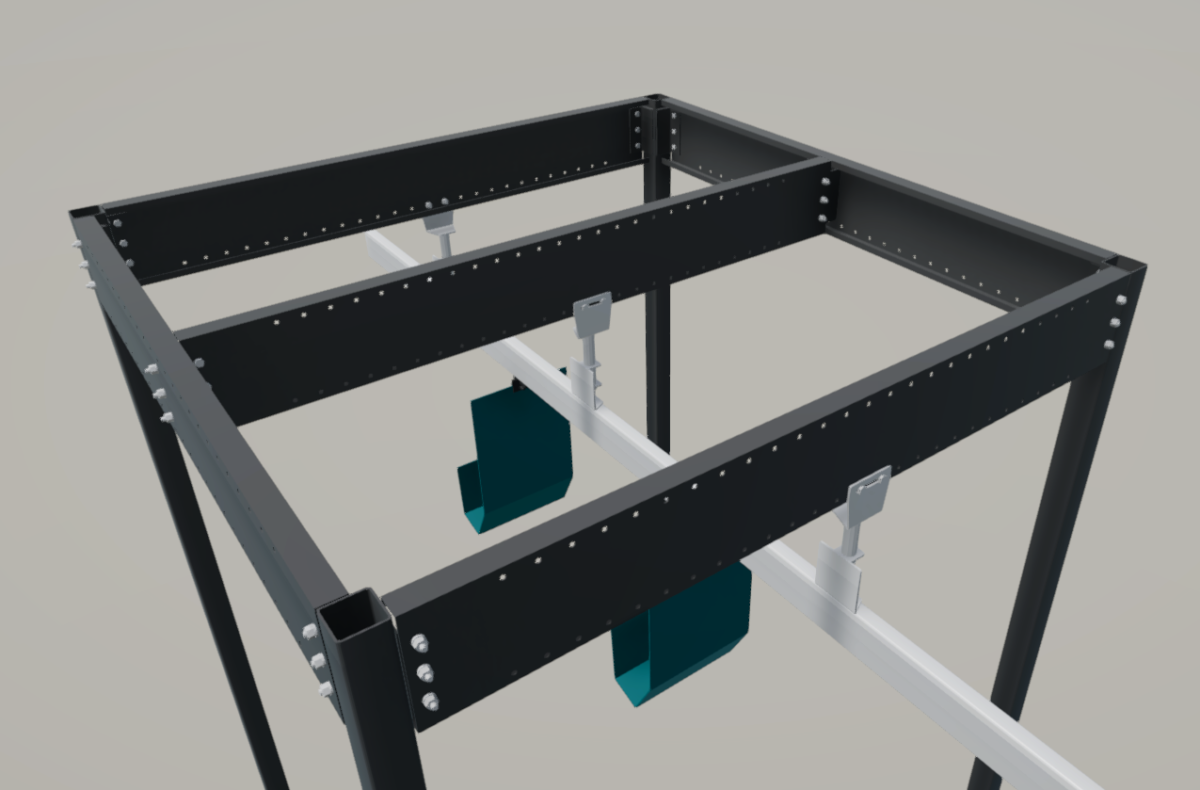

SteeleTrax structural steel framing members are engineered to integrate seamlessly with Steele Solutions’ platform systems, enhancing the efficiency of your operations.

- Available in various profile depths and thicknesses, the C-Section with pre-fabricated holes enables fast and precise installation.

- Reduces the need for field drilling, lowering labor time and costs while ensuring accurate alignment and installation.

Whether used in decked platforms or open-grid structures, SteeleTrax is a reliable, high-performing solution for supporting suspended equipment in material handling environments.

Steel Framing Members Built to Last

Steele Solutions’ engineering team works closely with customers to develop the most efficient SteeleTrax framing layout to meet building codes and structural requirements, ensuring optimal performance and reliability.

Framing Member Specifications

- Available Profile Depths: 8 – 18”

- Available Thicknesses: 14-gauge – 1/4”

- Max Member Length: 20’

- Powder-coated finish

Standard Hole Pattern Specifications

- Holes spaced 50mm on center

- ½” diameter holes located along both the top and bottom of the member

- Holes located 1” from top and bottom edge of member

- Hole pattern can be modified to meet system requirements

Gallery

Structural Steel Framing Member FAQs

SteeleTrax is designed to support a wide range of suspended equipment, including pocket sorter conveyors, fire suppression systems, lighting, conduit, and other mechanical, electrical, and plumbing (MEP) equipment. Its versatile design and prefabricated hole pattern ensure secure and efficient installation for various material handling and warehouse operations.

Yes, SteeleTrax structural steel framing members can be customized to meet your specific project needs. Customization options include adjustable hole patterns, various profile depths (8 -18”) and multiple thicknesses ranging from 14-gauge to 1/4”. Our engineering team works closely with customers to ensure SteeleTrax integrates seamlessly with their system requirements, optimizing performance and installation efficiency.

SteeleTrax saves on installation costs by significantly reducing the need for on-site drilling with its prefabricated holes spaced 50mm on center. This streamlines installation, reduces labor time, and minimizes errors, ensuring faster, more precise installation of suspended equipment. Additionally, the modular design allows for seamless integration with Steele Solutions’ platform systems, further reducing project complexity and associated labor costs.

SteeleTrax is designed to integrate seamlessly with Steele Solutions’ platform designs. Whether used in decked platforms or open-grid structures, SteeleTrax enhances the functionality of your operations while maintaining structural integrity and compliance with industry standards.

SteeleTrax is proudly made in the USA at Steele Solutions’ state-of-the-art facilities.