STEEL CHUTES

Improve Workflow with Custom-Designed Steel Chutes

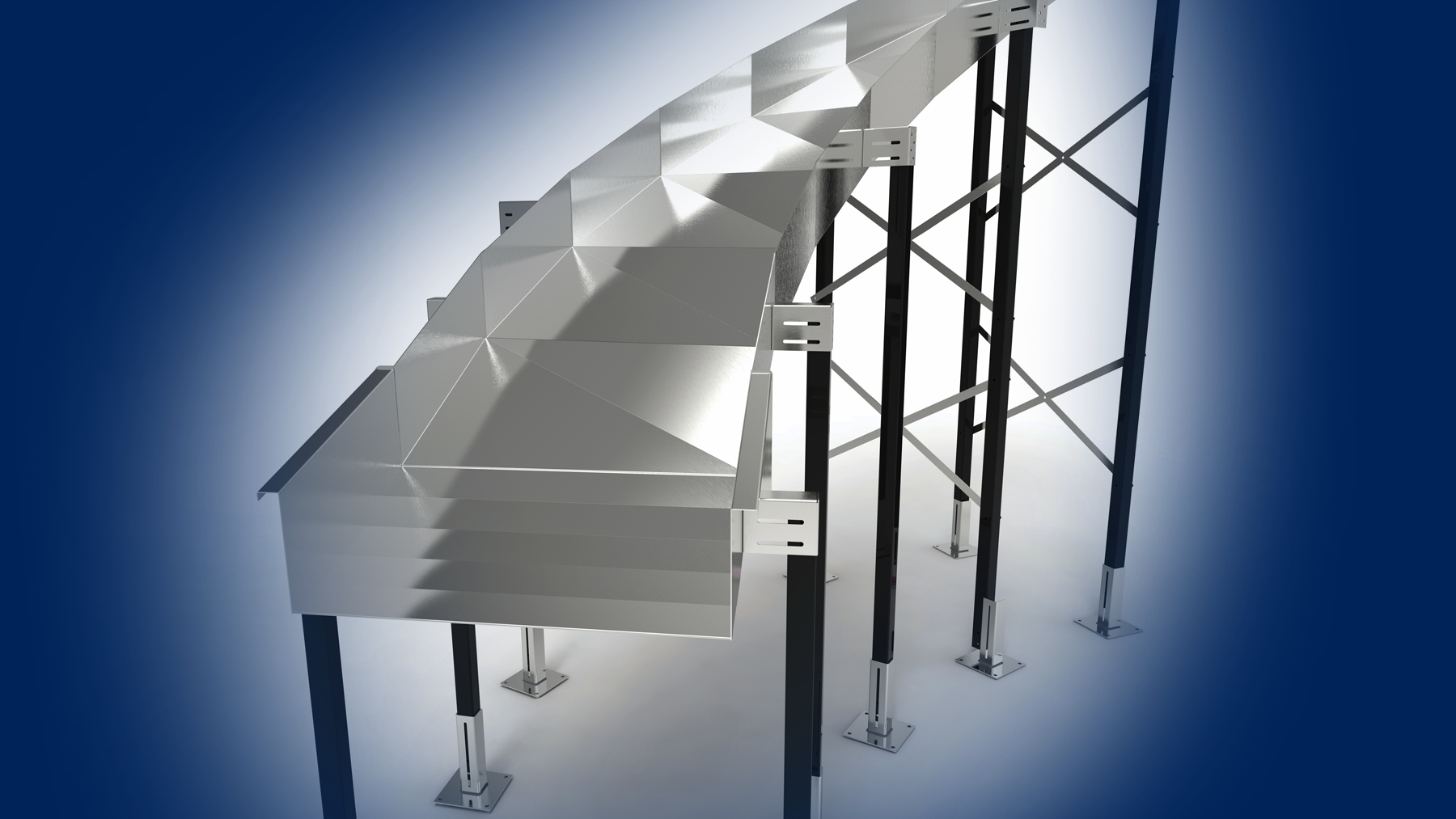

Steel gravity chutes enhance operations by enabling more efficient movement of materials throughout a facility. Our expert engineering team combined with our precise manufacturing enable us to create customized steel chute solutions tailored exactly to your needs.

Steel Chutes

We have designed, manufactured, and installed a variety of steel gravity chute types in locations around the world. Straight, Spiral, Sorter, and Transition steel chutes are all common types used in distribution, sortation, and manufacturing facilities. We also specialize in other chute types such as chimney, snowplow, and butterfly chutes.

Don’t see what you’re looking for? Don’t sweat it. Our experienced team will design a unique solution based on your application and requirements.

Straight chutes are the most common chute, characterized by their direct, linear design. Often found in manufacturing, logistics, and recycling facilities, straight chutes are ideal for applications where materials need to be transported in a straight path without any changes in direction.

Straight chutes are the most common chute, characterized by their direct, linear design. Often found in manufacturing, logistics, and recycling facilities, straight chutes are ideal for applications where materials need to be transported in a straight path without any changes in direction.

Straight chutes can be modified in height and width to accommodate different types of products or materials. The entry and exit points can also be tailored to integrate seamlessly with existing equipment or workflows, making them highly versatile.

Spiral chutes are designed to transport products from one elevation to another, utilizing a spiral, helical path. This design ensures a controlled, gentle descent of items to reduce the risk of damage during transportation while saving floor space.

Spiral chutes are designed to transport products from one elevation to another, utilizing a spiral, helical path. This design ensures a controlled, gentle descent of items to reduce the risk of damage during transportation while saving floor space.

Spiral chutes are commonly used in e-commerce fulfillment centers, food processing plants, and distribution warehouses. They can be equipped with either a single entry point, where items enter from one location, or multi-entry points, allowing items to enter from multiple locations along the chute’s spiral path.

Sorter chutes facilitate the movement of products between different elevations. The key feature of sorter chutes is the ability to sort and direct items to different destinations, making them essential for systems requiring precise product handling and distribution.

Sorter chutes facilitate the movement of products between different elevations. The key feature of sorter chutes is the ability to sort and direct items to different destinations, making them essential for systems requiring precise product handling and distribution.

Sorter chutes can have single or multi-entry points. This feature is particularly useful in environments where multiple products need to be routed to different locations based on sorting criteria.

Sorter chutes can be found in automated sorting facilities, mail and parcel sorting centers, and manufacturing plants.

Transition chutes are designed to handle the flow of products from one system or area to another, typically transitioning from a bulk flow area to a more controlled, specialized flow.

Transition chutes are designed to handle the flow of products from one system or area to another, typically transitioning from a bulk flow area to a more controlled, specialized flow.

Transition chutes are used in various industries, including packaging, sorting facilities, manufacturing, and distribution warehouses.

Maximize Material Handling Efficiency with Custom Steel Chutes

STEEL CHUTES

Gallery

Steel Chute FAQs

Steel gravity chutes are a critical asset in many industrial and commercial applications, including:

- e-Commerce

- Fulfillment Centers

- Postal and Parcel Sorting

- Retail Distribution

- Manufacturing

- Food Processing

- Recycling and Waste Management

- Agriculture

- Mining and Quarrying

- Aviation and Airport Operations

- Pharmaceuticals

To learn more about how steel chutes could benefit your operations, contact our team directly.

The four types of steel chutes are Straight, Spiral, Sorter, and Transition chutes.

- Straight chutes are ideal for transporting materials in a linear path without direction changes, making them versatile and customizable.

- Spiral chutes move products from one elevation to another using a spiral path, ensuring controlled descent and space efficiency.

- Sorter chutes facilitate the sorting and directing of items to different destinations, which is essential for precise product handling.

- Transition chutes manage the flow of products from bulk areas to specialized areas, aiding in the efficient movement between different systems.

Chutes can be customized in several ways to meet specific operational needs. Common customization options include adjusting dimensions like height, width, and length to accommodate different types of products or materials.

The choice of materials is also customizable, with options such as stainless steel or powder-coated steel to ensure durability and suitability for various environments.

Additionally, entry and exit points, as well as features like single or multi-entry options, can be tailored to integrate seamlessly with existing equipment or workflows. These customizations make chutes versatile solutions for a wide range of industries and applications.

The customization process for steel chutes, from design to installation, typically depends on the complexity and specific requirements of the project. Generally, it can take several weeks to a few months.

If you have unique requirements or tight project timelines, reach out to our team to see how we can help.

To ensure the longevity of your steel chutes, we recommend routine maintenance, including regular inspections for wear, corrosion, and damage, as well as cleaning to remove debris and prevent blockages. Additionally, lubricating moving parts and promptly repairing or replacing any damaged components can help extend the lifetime of your chute. Steele Solutions provides a detailed overview of maintenance requirements tailored to each chute system and is available to assist with any support or guidance needed to keep chutes in optimal condition.

Steel chutes must adhere to various industry safety standards and regulations to ensure they operate safely and effectively. For example, the Occupational Safety and Health Administration (OSHA) mandates proper chute design, installation, and maintenance to prevent accidents and injuries.

Additionally, industry-specific standards, such as those for food processing or pharmaceuticals, may require chutes to be made from materials that are hygienic and easy to clean.

Steele Solutions is committed to ensuring all steel chutes comply with the necessary industry regulations, providing peace of mind and safety for users.

Yes, additional safety features can be integrated into steel chute designs to enhance safety and functionality. These features may include safety guards or barriers to prevent accidental access or contact with moving parts, non-slip surfaces to reduce the risk of falls, and automatic shut-off mechanisms in case of blockages or malfunctions. Emergency stop buttons and safety sensors can also be incorporated to halt chute operations if unsafe conditions are detected immediately.

Steele Solutions offers safety features tailored to meet the specific needs and safety requirements of each client. Contact our team to learn how to get started.